Refratechnik Hybrid Castables:

Also suited for low temperatures.Our new hybrid castables permit fast heating combined with high strength – also at low temperatures. This offers advantages in the production of prefabricated components or the lining of e.g. fluidized bed furnaces and refuse incineration plants.

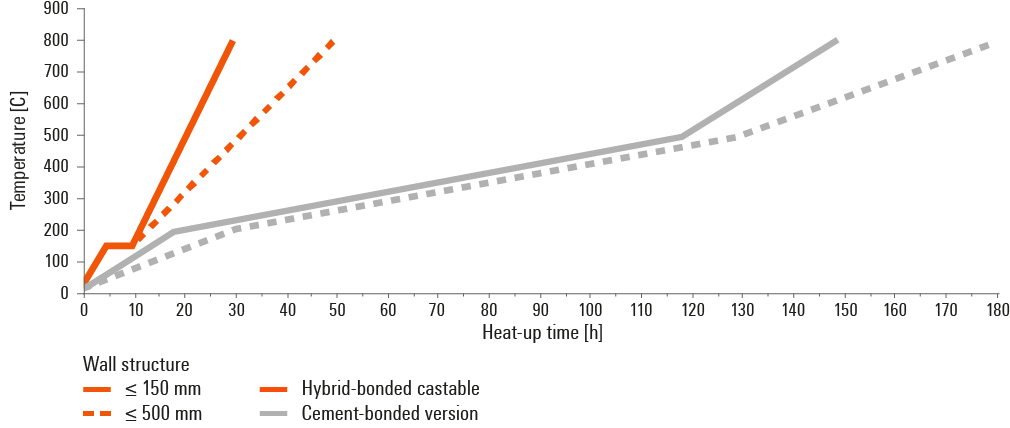

Hybrid-bonded castables have shorter heat-up and downtimes

than cement-bonded castables.

Hybrid-bonded castables and

conventional Sol-Gel-bonded castables.

The technology of cement-free Sol-Gel-bonded refractory castables makes another step forwards.

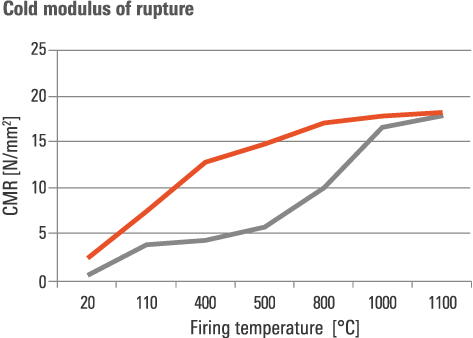

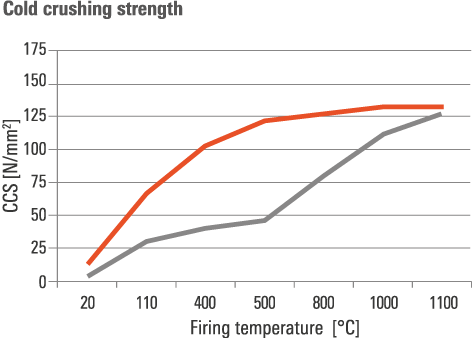

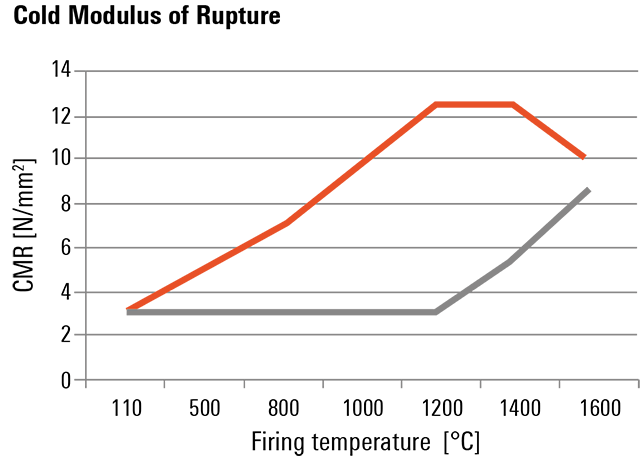

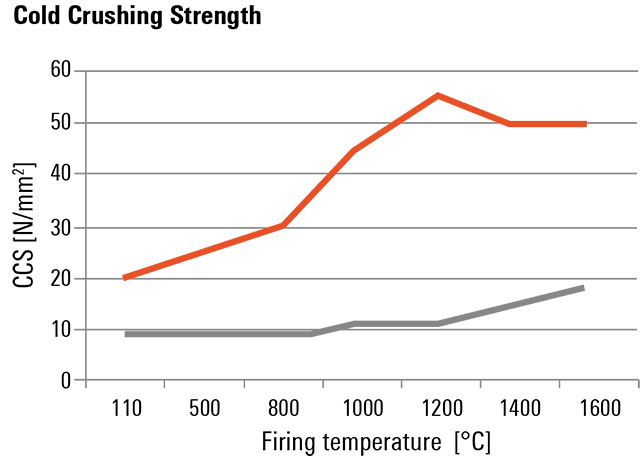

Strengths of REFRACAST® Hybrid F-60 AR/R compared with a conventional Sol-Gel-bonded refractory castable: Clear advantages for Hybrid

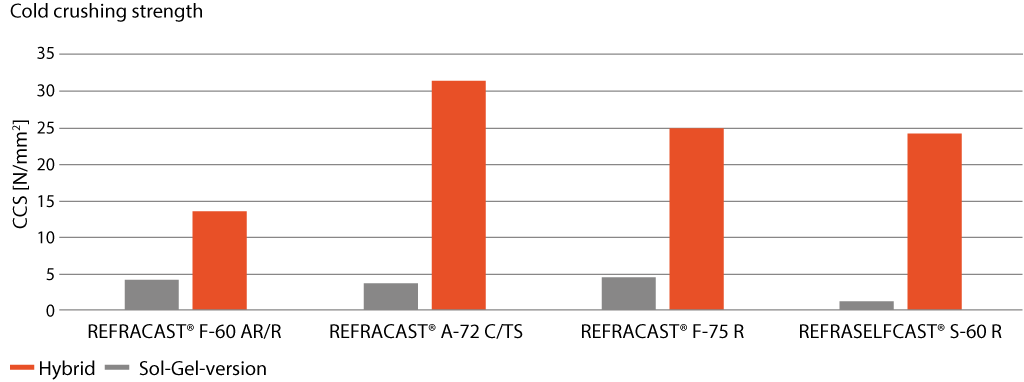

Cold crushing strength of Hybrid castables and conventional Sol-Gel-bonded castables at 20 °C/24 h: Hybrid castables exhibit a significant increase in cold crushing strength

HYBRID – Optimized Sol-Gel-technology.

HYBRID – Optimized Sol-Gel-technology.

Download Broschure

New: Hybrid-bonded insulating castables –

impressive properties up to 1700 °C.

Up to 5 times higher strength compared with cement-bonded insulating concrete based on bubble alumina.

A perfect choice for everyone planning to work with new synthetic fuels in future. This material is excellently suited for use in reducing atmospheres at high temperatures. Its impressive physical properties permit it to be used at temperatures up to 1700 °C, also under high loads. Outstanding savings in time and energy, thanks to hybrid bonding and good insulating properties.

REFRACAST® Hybrid MW 1700 R highly resistant covering layer with convincing insulating effect. A unique, hybrid-bonded insulating castable based on bubble alumina for demanding conditions. Impressive physical properties up to 1700 °C.

Advantages of Hybrid castables:

- Faster heating up with shorter downtimes

- Cost and energy-saving

- Very good adherence on existing refractory materials

- Installation possible on hot surfaces and with high ambient temperatures

- Higher application temperature limits

- Optimized thermomechanical behaviour

- Long storage life of 12 months

- Increased cold crushing strength and modulus of rupture as well as optimized abrasion resistance in the temperature range below 1000 °C.

- Safe handling of untempered components